Density calculation for polymer materials

Case study provided by: Institute of Science Tokyo

Introduction

Polymer materials have a wide variety of applications, including in optical devices such as thin lenses.

When designing molecules for such optical applications, it is necessary to predict the refractive index.

One of the factors that greatly affects the refractive index is material density. However, when trying to take into account intermolecular interactions and packing conditions, etc., there was an issue that the calculation costs would increase significantly.

Therefore, we investigated a method to calculate the density of polymers using PFP and predict the refractive index.

Calculation Models and Methods

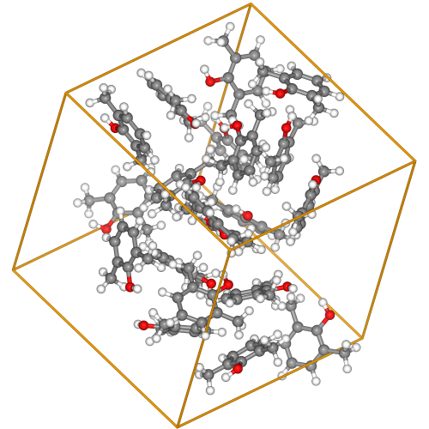

As an example of density calculation, we considered the unit structure of a polymer.

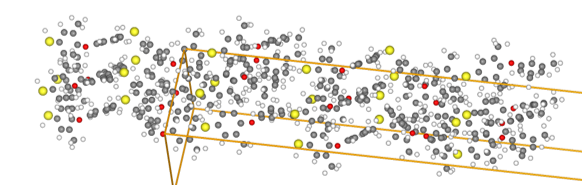

First, about 20 molecules were extracted from the unit structure and placed in a simulation cell. Then, the structure was optimized using PFP, and the density was estimated from the results.

In addition, to confirm the reproducibility of the results, we randomly generated 10 models with different initial molecular configurations and performed the same calculations on each.

Results and Discussion

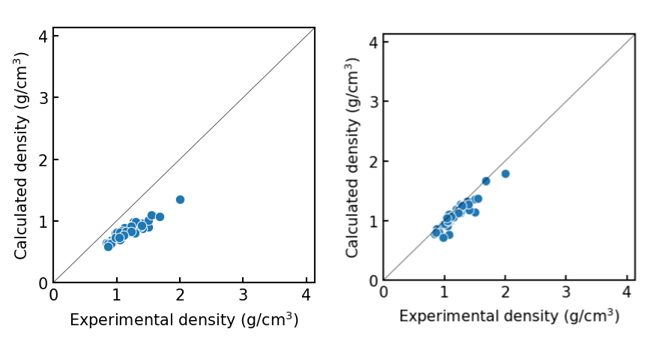

The density was calculated for approximately 40 types of high refractive index polymers listed in the Polymer Database.

As a result, the correlation coefficient between the calculated density and the measured value was 0.93, which was a high agreement (upper figure left). This value was better than the value calculated by assuming a single molecule in vacuum using the RDKit module. On the other hand, the predicted values by our method generally tended to be lower than the measured values. This is thought to be because the molecules were not modeled as polymer chains in the simulation. To solve this problem, we performed additional simulations of the packing state using an oligomer with five units linked together, and confirmed that the systematic error almost disappeared (upper figure right).

In the future, we will continue to search for polymers with high refractive indices by taking advantage of PFP's high precision, speed, and versatility. In addition, PFP is not limited to this application, and it is believed to be becoming a powerful tool for delving into the hierarchical structure of organic materials.

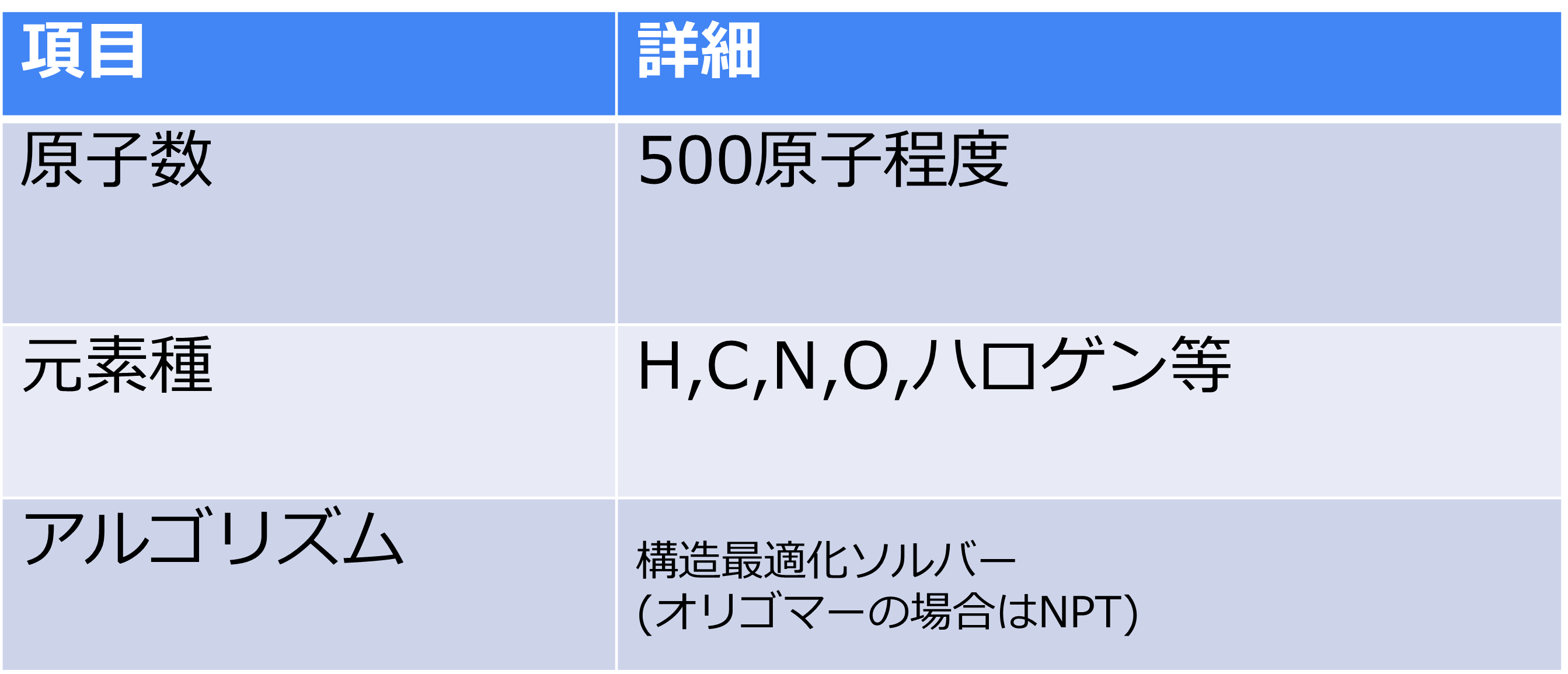

Simulation Conditions

References

[1] Kan Hatakeyama-Sato, Seigo Watanabe, Naoki Yamane, Yasuhiko Igarashi, Kenichi Oyaizu, 2023 https://chemrxiv.org/engage/chemrxiv/article-details/64754871be16ad5c5722fda7Profile of the case study provider

Institute of Science Tokyo

tag

Publication date of this case: 2023.06.16