High-speed, general-purpose atomic-level simulator revolutionizes catalyst development

- ENEOS Corporation

- Industry: Oil and Coal

- Business: Refining and marketing of petroleum and petrochemical products

From left to right: Yukihiro Sugiura, Ph.D., Chief Researcher, Renewable Technology Group, Central Technical Research Laboratory / Yuichiro Fujiyama, Ph.D., General Manager of Central Technical Research Laboratory/ Yoshihiro Yayama, Senior Staff, Data Science Group, Central Technical Research Laboratory

By using Matlantis, simulation tasks that would have taken 20 years with a conventional method was completed in only a week. This has shortened our catalyst development process to one-tenth of the previously required time. Matlantis has unlimited potential throughout the materials industry.

Yoshihiro Yayama, computational chemistry specialist

“The long process time was a big issue with the conventional molecular simulation methods. Matlantis’s calculation speed is overwhelmingly fast and allowed me to provide immediate feedback to my colleauges doing the experiments. For example, a calculations task that would take around 20 years was completed in only one week. We can quickly test a variety of elements and the results often surprise our experiment team.”

Yukihiro Sugiura, Ph.D., catalyst engineer

“When we develop new catalysts, we have to prepare dozens of combinations of metals and catalyst carriers and evaluate them, which can take over a year. Matlantis suggests specific metals to aim for, and we’ve reduced the time required to a tenth or maybe less.”

Yuichiro Fujiyama, Ph.D., Executive Officer

“In a sense, Matlantis has no limit to how it can be used as it can simulate all kinds of materials such as metals as well as catalysts. As the materials and substances that the world needs change dramatically, it is my hope that Matlantis can be used as a tool to accelerate this change.”

Q. How does Matlantis differ from existing molecular simulation techniques?

Conventional molecular simulation methods required a lot of calculation time—a single calculation might take up to a week. What was overwhelmingly different about Matlantis was the calculation speed. What used to take one or two days now finish in an instant, allowing me to provide immediate feedback to my colleagues doing the experiments.

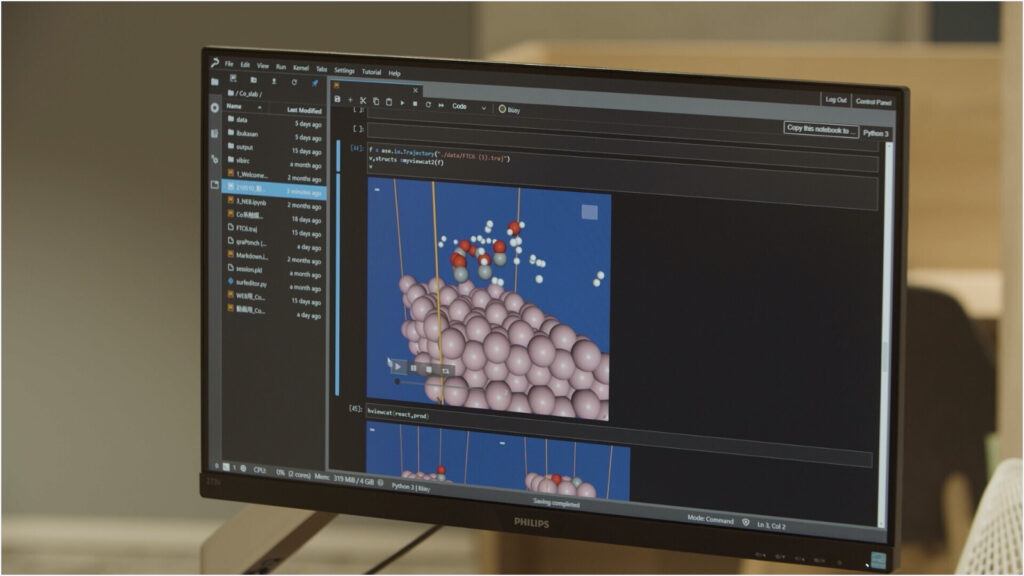

Matlantis can simulate this chemical reaction in which hydrogen and carbon monoxide combine to form hydrocarbon fuel, for example. The simulation of the activated energy proceeds rapidly.

Normally this kind of calculation would take several days, but with Matlantis we only need about 10 minutes. With calculation this fast we were able to perform around 10,000 simulations. Calculation tasks that would take around 20 years were completed in only one week. We performed brute-force simulations with all kinds of elements, and found out some combination of elements can accelerate chemical reactions. We presented the results to our experiment team.

The results surprised the experiment team because some of the combinations of elements are quite unexpected.

Q. How did Matlantis help your catalyst development process?

I am responsible for the development of energy-related catalysts for refining oil and producing synthetic fuels. When we develop new catalysts we have to prepare dozens of combinations of metals and catalyst carriers to evaluate them.

We must repeat this process of trial and error, which takes a large amount of time. We have built up experience, but this method can still take over a year.

Matlantis suggests specific metals to aim for, which can greatly reduce the number of trials and errors to prepare and evaluate catalysts. I think we’ve reduced the time required to a tenth, or maybe less. There were some combinations we avoided,but Matlantis sometimes suggests them and they tested well.

To me, the great thing about Matlantis is how it suggests combinations of metals and catalyst carriers that we would never have imagined based on our own intuition and experience.

Q. What does it mean for ENEOS to search for new materials using Matlantis?

We are, after all, an energy company, and have always worked with oil and fossil fuels thus far.

But with the coming move to a low-carbon society, energy will take on a whole new form. What kind of substance will we base that energy on, and what kind of processes will we use to convert one form of energy into another? I believe that we can use Matlantis to improve efficiency in such chemical reactions, and in many other areas.

We can also use it for other materials such as metal. Behavior of all kinds of materials can be simulated with Matlantis.

I think that for amy industry working with materials and substances, there is—in a sense—no limit to how it can be used. As the materials and substances that the world needs change dramatically, it is my hope that Matlantis can be used as a tool to accelerate this change.

*Company names and product names appearing in this document are trademarks or registered trademarks of the respective companies.

*The information is current at the time of the interview.

Published: July 1, 2021