2025.10.30

A new model for doctoral education pioneered through industry-academia collaboration: A "new pilot case" demonstrated by Institute of Science Tokyo and Taiyo Yuden Practice School

We will not only keep doctoral candidates as successors in academia, but also transform them into a force that can play an active role at the forefront of society and business.

Taiyo Yuden has participated in the "Practice School," an industry-academia collaborative program run by Institute of Science Tokyo.

In this program, doctoral students are stationed at a company's research site for six weeks, where they face real-world problems and attempt to solve them. A distinctive feature of the program is that students from diverse backgrounds across faculties, such as experimental and information science, participate and work together in mixed teams. The students tackled actual development challenges at the company's research center. The AI atomic-level simulator "Matlantis" was also utilized in tackling these challenges, enabling trial and error in a short period of time.

We spoke with Professor Ryo Maezono of the Materials Science and Information Sciences Department of the School of Materials and Chemical Technology at Institute of Science Tokyo, who is responsible for developing doctoral candidates, and Yuki Sakai of the Materials Science Laboratory TAIYO YUDEN CO., LTD., the company that welcomed the students, about the background and significance of this program.

Realistic industrial challenges train doctoral students

--Please tell us about the background and purpose of the practice school being run in collaboration with industry and academia, and the significance of this program.

Professor Maezono: First, I would like to talk about the overarching idea behind this initiative. This means rethinking how society perceives doctoral candidates. In Japan and other parts of Asia, doctoral candidates have long been narrowly perceived as "successors to scholars." In contrast, in Europe and the United States, doctorates are seen as a group of people involved in planning and drafting projects for society as a whole, and there is a strict belief that without a doctorate, you cannot even be involved in planning.

In order for Japan to raise its "development of highly skilled human resources to take on social planning" to an internationally recognized level in the future, it is first necessary to raise students' awareness of "honing their problem-solving skills." A doctor's ability lies not in a history of acquiring specialized skills, but in the ability to plan and develop a model when faced with an unexplored real-world problem, and how to put it into concrete action.

For this reason, group discussions are often held, but they inevitably end up being unrealistic "toy problems." Students end up thinking, "There's no point in discussing such a toy-like topic." Instead, it is in the research section of a company that leads to outputs for society that graduate students' "awareness of problem-solving ability" can be best developed.

This realization was made at MIT over 100 years ago, and was utilized in graduate education as a practice school, focusing on chemical engineering, which was the field at the time where science and industry were most directly connected. This is the reason why we chose the industry sector. It has a different philosophy than simple "industry-academia collaboration" or "interns for employment."

If the 20th century practice school focused on chemical engineering, our 21st century subject is "data-driven materials development." Chemical engineering challenges take too long to come up with an idea, conduct an experiment, and get results, making it difficult to complete a trial-and-error cycle within a six-week period. By contrast, the use of simulation and machine learning makes it possible to conduct multiple trials and investigations in a short period of time. Information technology is interdisciplinary, seamlessly connecting everything from manufacturing to service development, making it easy to discuss.

--So the goal is to change the way doctorates are perceived in Japan as well, so that they can be used to solve problems not only in academia but also in companies.

Ryo Maezono, PhD,Managment Professor. Graduate Major in Materials and Information Sciences, Institute of Science Tokyo

--Why did Taiyo Yuden decide to participate in this initiative? Please tell us the reasons and objectives for cooperating again this year following last year.

Mr. Sakai: Last year, despite the short six-week period, we were able to produce high-quality results, and we employees were also greatly inspired by the students' free-thinking. We felt that we were able to come into contact with ideas and answers that we would not have been able to reach if we had only been thinking within the company.

Furthermore, this practice school was held at TAIYO YUDEN's Shin-Kawasaki Center, "SOLairoLab." This is TAIYO YUDEN's research and development center established to promote collaboration with external parties, and is a place where new initiatives are launched in an open manner. In that sense, I feel that it is a perfect fit with the concept of this program.

Not only does it produce tangible results, but it also has great value as an opportunity to build relationships through interaction between employees and students and to encounter new perspectives. With these expectations in mind, we participated again this year, just like last year.

--We understand that the students were stationed at Taiyo Yuden's offices during this Practice School. What kind of location was it, and what themes did they tackle? Please tell us about how the activities were carried out, how the themes were decided, and the distinctive aspects of the initiatives.

Professor Maezono: The students were stationed at the Shin-Kawasaki R&D base for six weeks, working daily. What was important was that they dealt with real problems that companies actually wanted to overcome, in other words, real data that could not be released to the public. This time, five problems were set, and teams of two to three students were formed. Furthermore, we tried to combine students from different faculties and specialties as much as possible, and placed importance on working in a mixed-disciplinary team structure.

The tasks that students will work on are also selected through approximately six months of advance discussion between Taiyo Yuden and the university, with the level of difficulty and scope carefully examined to ensure that students can complete the entire process from modeling to analysis, consideration, and proposal in six weeks. Another unique feature is that the students are not informed of the theme until just before the program begins. This is because the emphasis is on problem-solving ability, on how to break down an unknown problem and find a solution, rather than thinking about whether they can utilize their existing knowledge.

Sakai: We began discussing the selection of the theme with the university around the beginning of the year, and after several meetings we finally decided on it. It was important to determine what results could be achieved in six weeks, and some themes are highly challenging and open, while others are easier to predict how to proceed. We adjusted the themes to allow for some flexibility, while still allowing us to see each task through to the end.

AI and the cloud are changing the barriers to experimentation and computation

--What level of experience and knowledge did the students who participated this time have in materials development and calculations? Please tell us about their backgrounds.

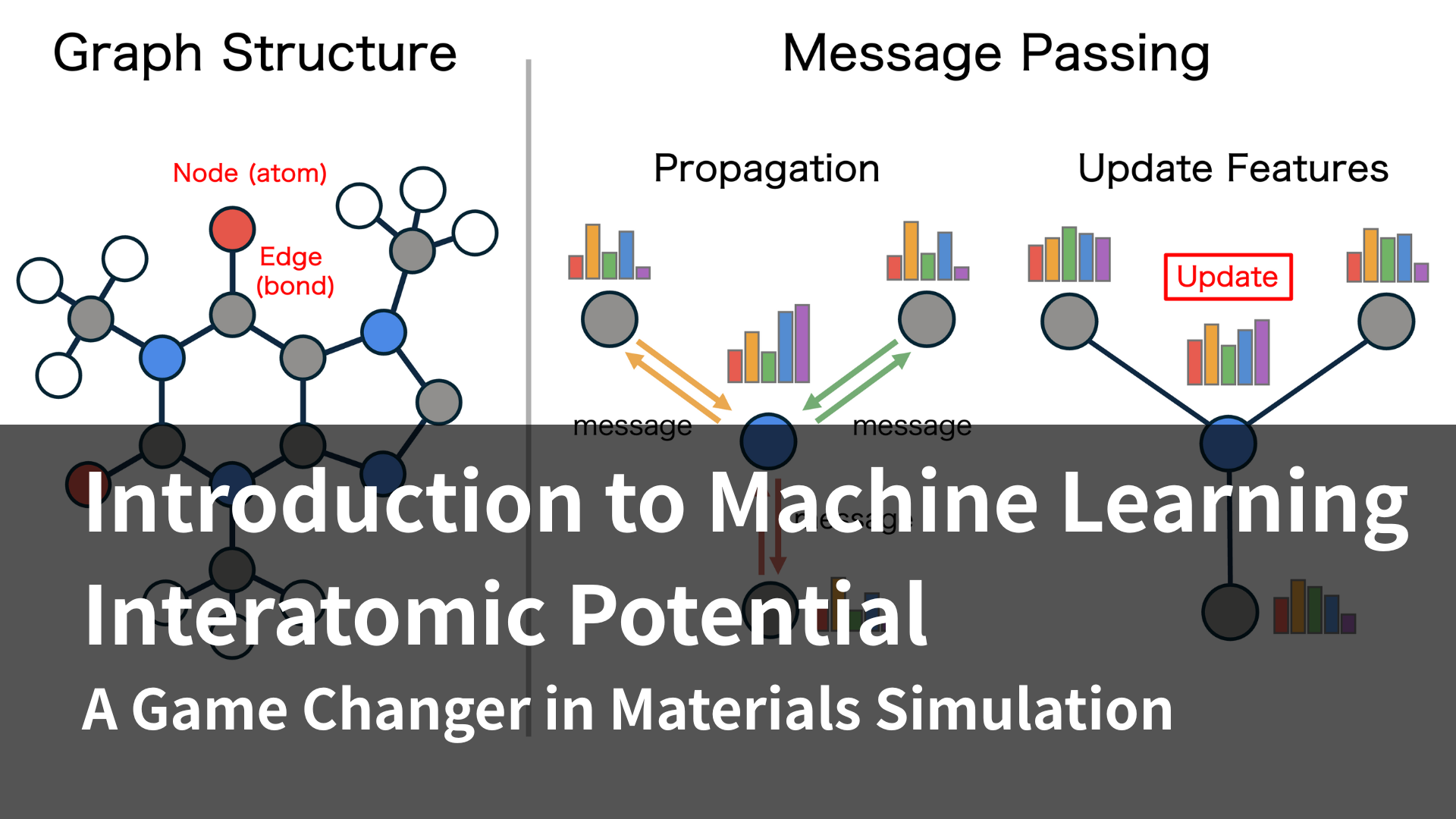

Professor Maezono: The majority of the participating students this time were primarily engaged in experimental research. There were actually only a few students specializing in information technology techniques. However, the course is designed so that students take basic subjects such as "Materials Simulation," "Materials Informatics," and "Fundamentals of Materials Information" at the master's level before taking on the practice school in their first year of doctoral studies. They take this course after gaining experience in the use of supercomputers, the basics of first-principles calculations, and the concepts and practice of AI.

With the spread of generative AI in recent years, even basic skills such as Linux operation, which were previously a barrier, have become less difficult to master. Full-time faculty members keep up with the ever-evolving tools, making efforts to ensure that the educational content does not become outdated.

--So it's an educational design that takes several years, starting with a solid foundation at the master's level and then tackling practice school in the doctoral program. And the faculty is keeping up with the ever-advancing AI tools and reflecting them in the curriculum. Thank you.

Yuki Sakai,PhD. Material Science Laboratory TAIYO YUDEN CO., LTD.

--Mr. Sakai, as you interact with students at the practice school, do you feel that the use of AI is playing a role in filling in the gaps that students have?

Sakai: Yes. There are an increasing number of cases of using simulation tools and AI at universities across the country, and I feel that students are getting up to speed very quickly before actually starting to work on calculations. Even if they start with tutorials or introductory courses, many students are able to move on to automation and analysis of complex atomic models within a few days. I think this is largely due to the spread of generative AI.

The barrier between experiments and calculations has also changed significantly in the past few years. Students who primarily conduct experiments have a keen understanding of the issues at hand, so as long as the barriers to tools are lowered, they can use them in calculations autonomously. The development of cloud environments is also helping to support this trend.

--What changes and effects did you see as a result of actually using the AI atomic-level simulator Matlantis in this practice school?

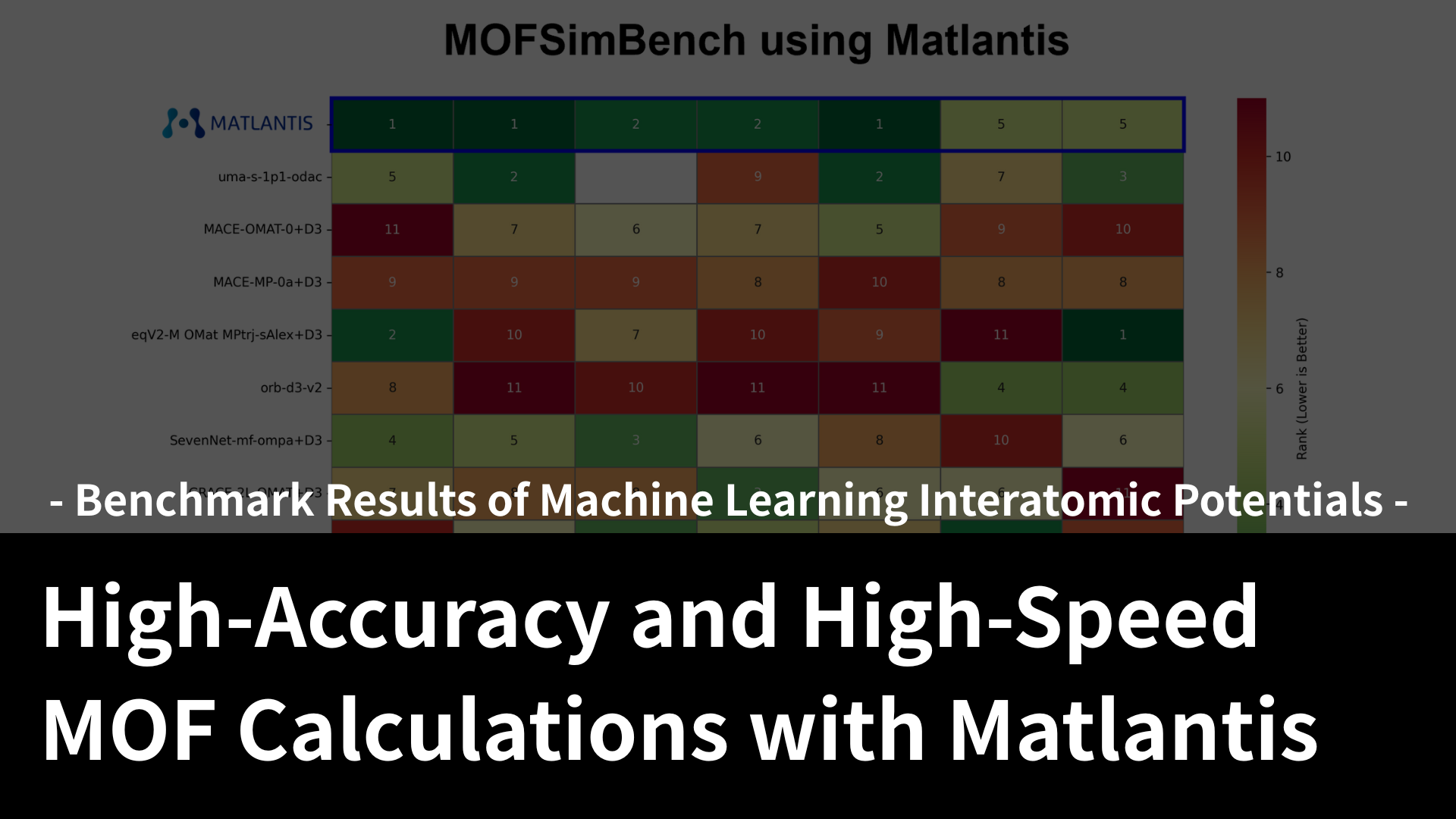

Professor Maezono: I mentioned earlier that the shift in subject matter from chemical engineering to computational chemistry has shortened turnover, but the addition of Matlantis has made things even better.

This program takes six weeks to complete the cycle of "modeling → analysis → consideration → proposal," and the speed of the learning cycle is extremely important. If each phase takes too long, the focus will inevitably be on mastering the techniques, making it difficult to develop a holistic view of problem-solving.

I once experienced a heavy calculation that only yielded one piece of data in six months. Even after handing over the results to the experimenters six months later, the memory and enthusiasm had faded, and the discussion did not continue.

On the other hand, when the cycle of "think → act → see the results" is completed in a short time, the level of insight development changes qualitatively. Machine learning tools like Matlantis are easy to set up, intuitive to use, and can be iterated on in a short time. I strongly feel that doctoral training has entered the next stage.

--What was it like for the students to actually use Matlantis?

Professor Maezono: The students were so active that they even shared the amount of resources they used with each other. Because the cycle from idea to verification was fast, they quickly mastered automation techniques, such as using an automated script to examine how results would change when conditions were applied to the horizontal axis.

Molecular dynamics allows direct access to realistic systems and allows the results to be "visible," which greatly increases student motivation. In the past, it was difficult to infer phenomena from the results of first-principles calculations, but molecular dynamics has the advantage of being able to treat them observationally.

What was also striking was the way the younger generation used tools. They came up with innovative ways to calculate the bulk modulus and apply external fields (such as electric fields) that went beyond conventional thinking. I felt an explosive power to break through.

Sakai: This "explosive breakthrough power" is a great learning experience for us as a company. There are always implicit assumptions within the company, and we tend to think within those boundaries, but the students often made us aware of ideas that went beyond those boundaries, which was very stimulating.

--Were there any memorable student behaviors or stories from the program?

Professor Maezono: It was very impressive to see doctoral students working in interdisciplinary teams for six weeks, teaching each other, discussing and working together. They quickly identified their roles and became able to explain them in terms that their peers with different specialties could understand. In the process, horizontal connections were formed across departments, which will continue to function for the remainder of the doctoral program. I feel that a new community has been formed, different from existing clubs or specialized gatherings.

Furthermore, many students were only informed of the theme on the first day and were working on tasks outside their field of expertise. Even so, within a few days they understood the background, decided on their own how to proceed, and presented in front of everyone. Even if they seemed unsure of their direction midway through, by the final day they had properly compiled their output. I am always impressed by how quickly they grow.

Sakai: We also learned a lot from the students. I was particularly impressed by their ability to quickly catch up on tasks they had never encountered before and achieve results through trial and error. I strongly felt that the students were highly motivated and conscious. Even in the process of modeling the tasks while discussing them with company representatives, they charted a course in their own words. This process of growth itself was extremely valuable.

A new pilot case of doctoral education realized through industry-academia collaboration

--How would you like to develop this program in the future? Please tell us your outlook.

Professor Maezono: We will continue to share the results with you, with the understanding that this is a new pilot case for doctoral education.

Data-driven materials development is ideal for a 21st century practice school, as it has low barriers to specialization and can incorporate actual data from industry. Furthermore, this field tends to be dominated by industry, making it easy for people with a passion for high-quality research to enter the corporate world. Therefore, by implementing co-creation education with industry, with universities stepping into companies, we hope to create a path to overcome the problem of "not being able to verify results because we can't access data."

At the same time, we will implement a system to motivate participating companies to continue participating by presenting them with benefits such as recruitment, CI (corporate identity), and inter-company matching.For students, we will provide them with a clear mission and a vision of future treatment for doctoral students, and encourage their participation, including financial support.

In other words, universities themselves will implement a system that autonomously circulates people and funds, and return value to operating funds. Through this program, we hope to concretely lay out this new way of operating universities.

As I mentioned at the beginning, the idea of changing the way doctoral candidates are employed and the field's characteristics of data-driven materials development mesh with the advantages for companies, creating a structure that works well together. This is difficult in other fields, but I think it is an advantage unique to this field.

Mr. Sakai: Our company also plans to continue participating. We feel that it is very meaningful because it allows for industry-academia collaboration at a level of intensity that is different from normal collaboration. In the future, we hope to expand initiatives like the Practice School to other development fields.

TAIYO YUDEN CO., LTD.

TAIYO YUDEN CO., LTD. is an electronic components manufacturer founded in 1950.

The company is engaged in the research, development, production and sales of a wide range of electronic components, including capacitors, inductors and communication devices (FBAR/SAW), and is expanding its business globally.The company is characterized by its consistent approach from material development to commercialization, and its technological capabilities are highly regarded in a variety of fields, including electronic devices such as smartphones and tablets, as well as automobiles, information infrastructure and industrial equipment, where IT and electronics are accelerating.

For more information, please visit the following website:

Head office address: Kyobashi East Building, 2-7-19 Kyobashi, Chuo-ku, Tokyo

- Website: https://www.yuden.co.jp/jp/

Institute of Science Tokyo Materials and Information Sciences

Institute of Science Tokyo is a national university in Japan that offers world-class education and research, primarily in the fields of science and engineering.

Among these, the "Materials and Information Master's Program (TAC-MI)" is positioned as an advanced, interdisciplinary course that combines materials science and information science.

We cultivate talent who will take on the challenges of developing new materials and manufacturing, while incorporating data-driven research and the use of AI across a wide range of fields from basic science to applied technology.

For more information, please visit the following website:

Head office address: 2-12-1 Ookayama, Meguro-ku, Tokyo

- Website: https://www.tac-mi.titech.ac.jp/

tag